Building a car roof rack

I only very recently got my driver’s license, meaning that I’ve been fully utilizing my newfound ability to go to home depot at will. Unfortunately, the car which I claimed from my sister after she left for college doesn’t have the space to bring home anything of decent size or have roof racks. I would have simply bought a roof rack, but they cost several hundred dollars for a set, which seems massively overpriced to me. I figured the best solution would be simply to make my own roof racks with a combination of traditional construction techniques and 3d printing. It would give me a nice way of putting 3D printing to the test and also yield something very practical.

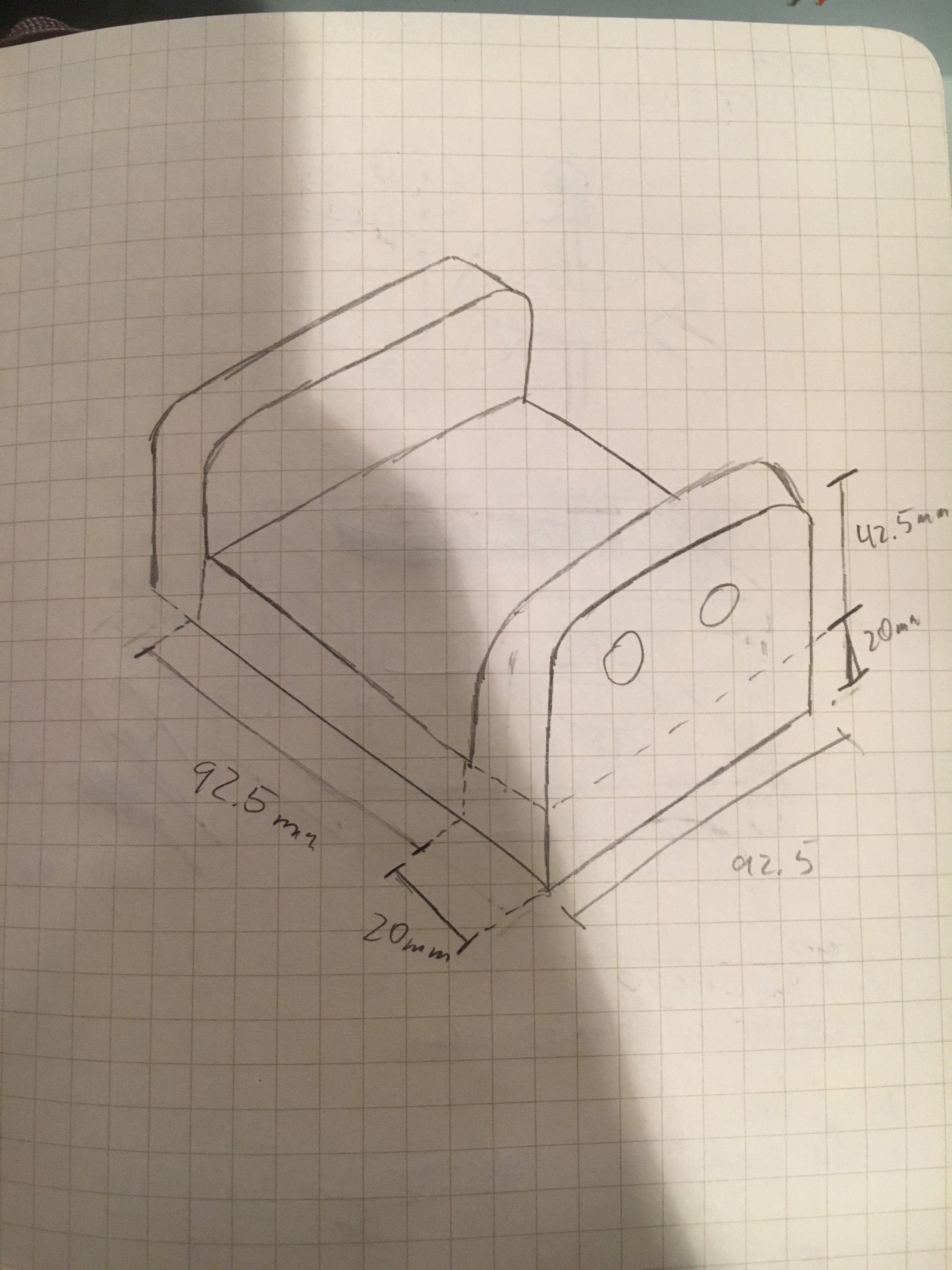

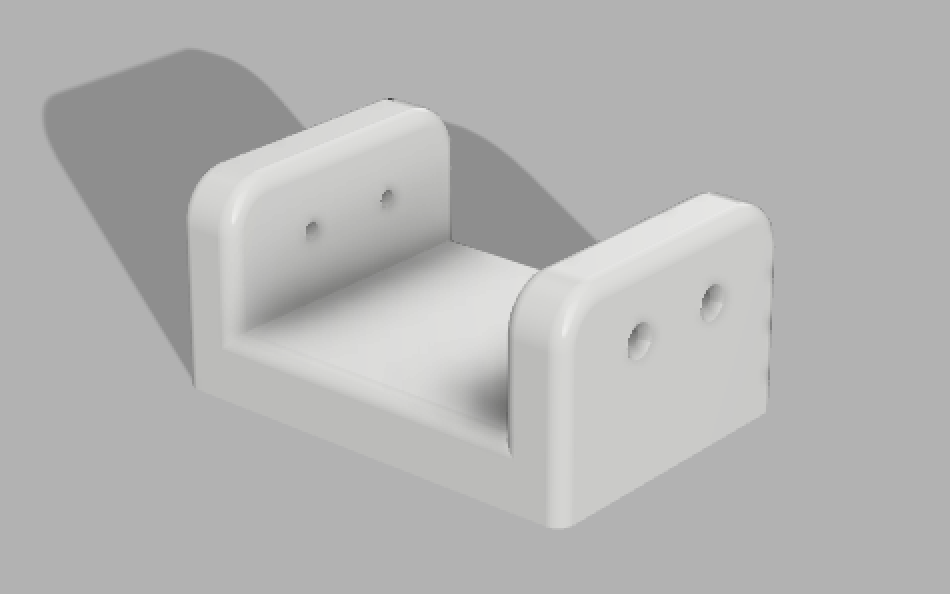

As with every project, I started by ideating in my notebook. I finally settled on a very simple design with two 2x4s held on my cars roof with 3d printed mounts on either end.

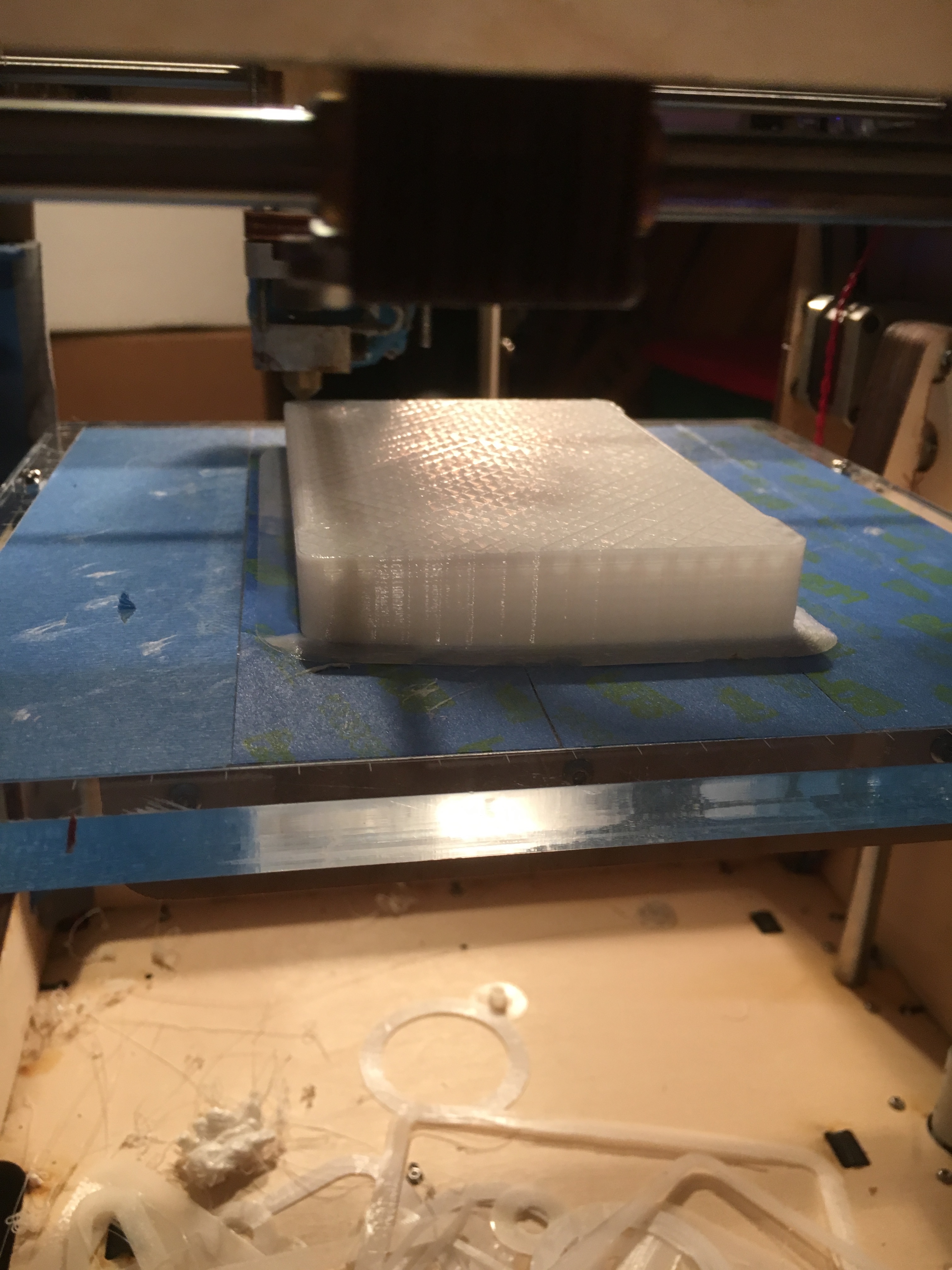

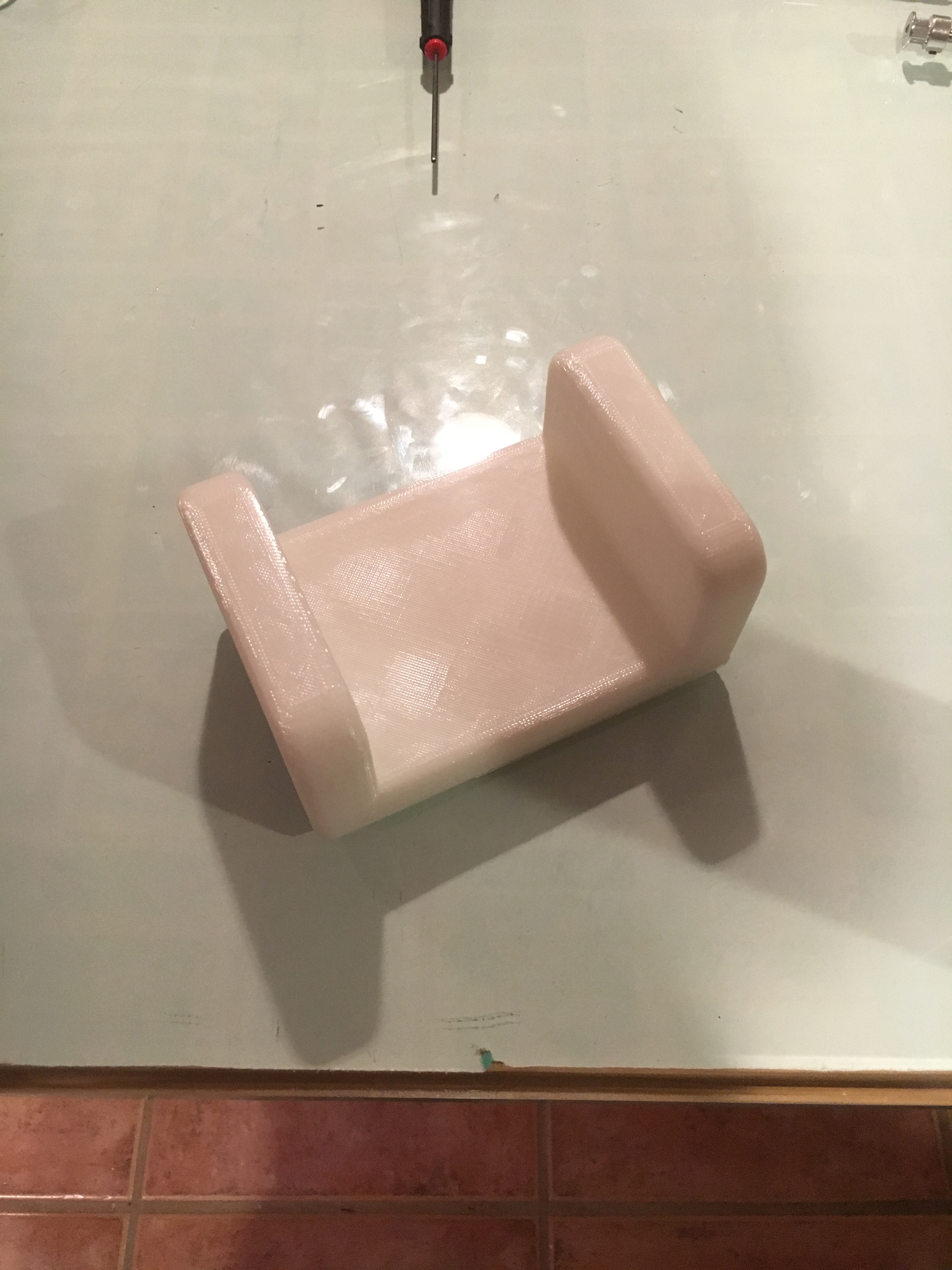

After slicing the model, I came to the realization that each of the four mounts would be a nine hour print, something that I have never attempted before because of the relatively inconsistent performance of my 3d printer. I continued on anyway, and I got very lucky with the first three prints, but ran out of filament during the last 10% or so of the final mount my first time through.

After slicing the model, I came to the realization that each of the four mounts would be a nine hour print, something that I have never attempted before because of the relatively inconsistent performance of my 3d printer. I continued on anyway, and I got very lucky with the first three prints, but ran out of filament during the last 10% or so of the final mount my first time through.

I then placed the back two mounts roughly where I wanted them on the car and then marked out holes to drill in the 2x4s. This was necessary because the roof of my car is slightly convex, meaning that mounts attached flat to the 2x4s wouldn’t have great contact with the roof of the car. They had to be mounted at an angle which I didn’t have the ability to measure, so I measured out the holes based on a fit.

I then placed the back two mounts roughly where I wanted them on the car and then marked out holes to drill in the 2x4s. This was necessary because the roof of my car is slightly convex, meaning that mounts attached flat to the 2x4s wouldn’t have great contact with the roof of the car. They had to be mounted at an angle which I didn’t have the ability to measure, so I measured out the holes based on a fit.

To add increase the friction between the bottom of the mounts and the roof of my car, I covered them with liquid electrical tape, giving them a rubbery surface.

To add increase the friction between the bottom of the mounts and the roof of my car, I covered them with liquid electrical tape, giving them a rubbery surface.

To actually attach the bars to my car, I used existing straps through the top of the doors.

To actually attach the bars to my car, I used existing straps through the top of the doors.

Before taking this out on the open road, I decided to attach a variety of load sizes and stress test my system in a parking lot. Everything performed as well as I had hoped for.

Before taking this out on the open road, I decided to attach a variety of load sizes and stress test my system in a parking lot. Everything performed as well as I had hoped for.